Welcome to Programme for Sustainable Charcoal Reduction and Alternative Livelihoods (PROSCAL) Application

In 2012, the UN Security Council passed Resolution 2036, which banned the export and import of charcoal from Somalia. PROSCAL was formed with the aim of coordinating international cooperation to support and implement the ban. The establishment of PROSCAL was the result of a direct request by Somalia’s Transitional Federal Government seeking support to reduce environmental destruction from rampant charcoal production and minimize the risks of local conflict arising from the trade. PROSCAL is an interagency programme implemented by the Federal Republic of Somalia, in collaboration with UN Environment Programme, UNDP and FAO and is funded by the European Union, and the Swedish and Italian governments.

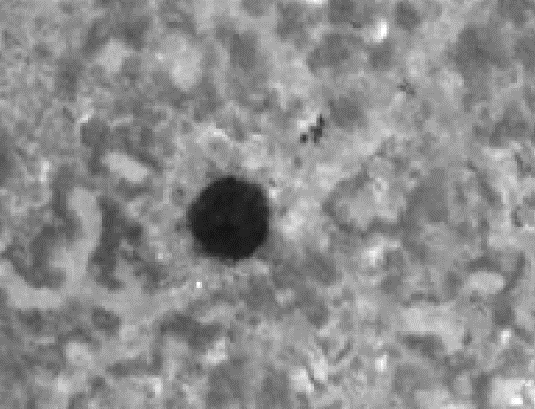

Following more than 20 years of civil unrest, environmental information for Southern Somalia is scarce while there is clear evidence that the war economy fuelled by the conflict is rapidly depleting the country’s natural resources, especially the woody biomass. Charcoal is a major fuel for domestic use.Larger and consequently denser trees are selected for charcoal production. Therefore, the main and preferred timber species is Acacia bussei. Large scale charcoal production concentrates first in areas where tree density is higher and distance from main roads, agriculture areas, and settlements is low, but also, as tree cover diminishes, new access roads are built to exploit areas further away. In Somalia charcoal is produced in ‘kilns’; a type of oven. The cut trees are piled up, covered with iron sheets, and buried with sand. After the oven burns for up to a week, the sand and sheets are removed. The wood has then turned into charcoal, which is then packed into bags/sacks ready to transport for export or domestic use Multi-temporal dataset of very high-resolution remote sensing images such as WorldView-1, 2 and 3 were used to map kiln locations in the study area. The acquisition dates of the images range from 2011 to 2017. Charcoal production sites can be seen on satellite images as dark round/ almost round patches. Many small tracks/ paths are a common feature at these sites. They are used for access and transport. The average radius of the kilns is 3.3m but some are as big as 6m in radius. Multi temporal analysis of vhr images reveals a tremendous increase of charcoal sites over the years.

The available information on charcoal production and export is limited and lacks continuity to establish trends over a period of time. FAO SWALIM has undertaken the monitoring of the impact of charcoal production on the natural vegetation and its dynamics. Through very high-resolution satellite images, it is possible to identify and count charcoal burning sites and to derive from them the number of trees cut per unit area and the amount of charcoal produced. SWALIM Remote Sensing Unit has regularly analysed satellite imagery of the representative areas and reported on charcoal production sites dynamics.

The charcoal production method carried out in the study area is known as the Bay Method, and it was described by Robinson (1988). To produce charcoal, a type of oven known as ‘kiln’ is used. Kilns are built by piling the timber straight on the soil floor. The timber is collected from the surroundings and arranged into a circular mound design, with stronger poles erected at the centre, and other shorter pieces of wood positioned around it. The mound is packed as close as possible, and the gaps are filled with smaller pieces of wood, shrubs, and grass to facilitate kiln lighting. The whole structure is then buried with sand and iron sheets. Once the burning process is completed, the charcoal is formed and it is loaded into bags, leaving a layer of black ashes on the ground that is visible on satellite VHR images.